The new dimension in the hemp and marijuana harvest

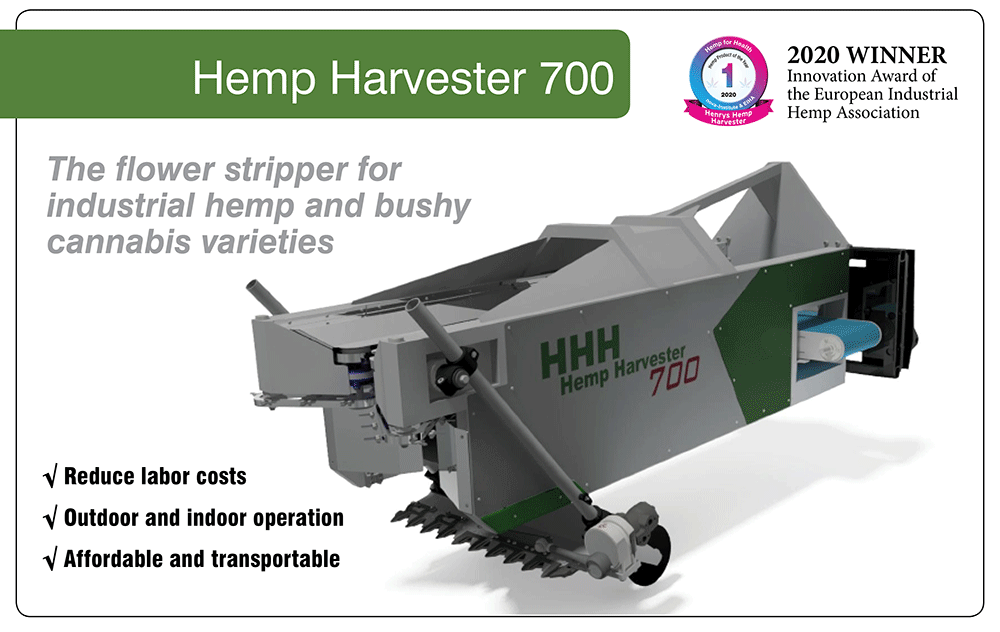

With the HHH Hemp Harvester 700, HHH Hemp Harvesting Technology presents a powerful device for harvesting hemp and cannabis flowers. The first season with the newly developed and patented stripping mechanism has proven its efficiency and robustness at four locations in different conditions. Both in industrial hemp for extraction flowers and with bushy varieties up to 1% THC, the HH harvester saved time and personnel and significantly increased the harvested area.

The Gamechanger in Hemp and Marijuana Harvesting

After excellent results with industrial hemp in Luxembourg and Germany the HHHarvester 700 has proven it’s versatility and durability in CBD Marijuana in Switzerland! With it’s outstanding performance our custmers have quadrupled their yield while they reduced their staff at 50%. And while working for the firrst three days with their new machine they just can’t fully utilize it because the drying space is the bottleneck now!

Read the article on Hemptoday.net

October 2020: The first HHHarvester proof performance in industrial hemp and in CDB Marijuana

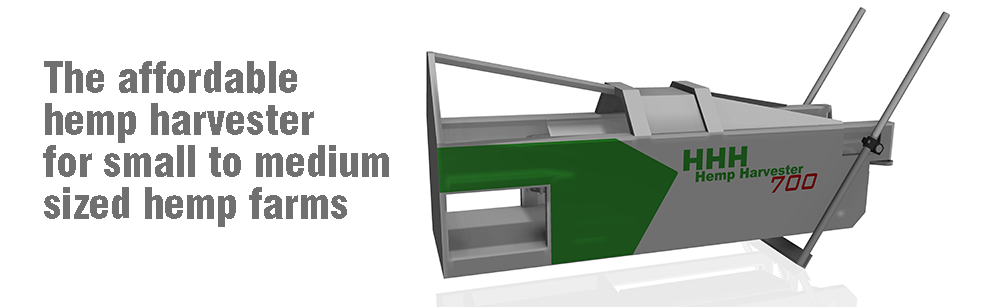

For family farms, specialty growers, cooperatives

Henry’s Hemp Harvester (HHH) brings dependability and unique customer engagement to the critical process of putting specialized hemp harvesting and processing equipment to work for your operation. With a basic two-unit model, our system opens the door for small and medium-size farms to gain efficiency, expand cropland and farmable acreage, and get an edge in overall competitiveness. With HHH technology, your hemp operation will gain independence from weather conditions that can be a headache for outdoor hand-harvesting operations. The harvester facilitates bud production in countries with high labor costs.

*Optional equipment, VAT and shipping extra

Harvest 0.25 ha (0.6 acres) per hour per module

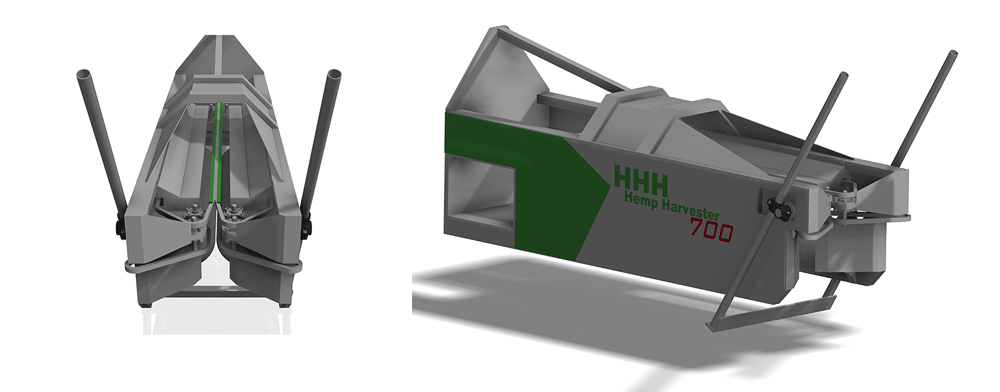

The HHHarvester gently strips the plant’s flowers and severs the stems in one pass, employing a patented stripping mechanism that collects flowers as if they were hand-picked. The flowers can be collected in a bag or container, while the hemp stalks are left in the field for retting. Depending on plant maturity at the time of harvesting, it’s also possible to shake out the seeds, completing a triple yield.

The HHH edge

We will engage very closely with our first customers as beta testers, and during the harvest will provide full service for spare parts, share our experience and consult on how to optimize the use of the technology. Key advantages of the HHHarvester:

- Quarter hectare (0.6 acres) per hour and a yield-quality like hand-stripped with one module

- Tea-quallity and pharmaceutically clean due to FDA compliance at all flower-touching parts

- Harvest up to 200 hectares per 60-day harvesting season (one double-module)

- Greater independence from weather conditions

- Exact bracketing of the harvesting schedule

- Independence from a posse of hand pickers

- Larger batches of unicannabinoid composition in your extracts

See the HHHarvester in action!

Partners

HempToday™ is the world’s leading source for information and networking in the fast-growing industrial hemp industry. We are advocates for industrial hemp through a family of business-to-business information, communications and educational initiatives which help hemp stakeholders all over the world connect with each other and work together toward the common goal of a vibrant, well-functioning hemp industry. Our network stretches from Europe to North and South America, Asia and Africa.

For more than 80 years, Eilhauer Maschinenbau GmbH has been your highly qualified and flexible partner for all mechanical engineering matters in contract manufacturing. The construction of special machines, from the solution concept to the turnkey plant according to specifications or customer drawings, from a single source, is the company’s specialty. ‘Specialty’ at Eilhauer also means the fastest possible production of spare parts ‘and all-round, well-functioning repair and maintenance service’.